Enterprise External Corrosion Management: Reducing Variability, Increasing Defensibility

Why consistent interpretation — not necessarily more data — determines program maturity. External corrosion surveys generate large volumes of...

5 min read

Sheri Baucom : Updated on November 17, 2025

Across the pipeline industry, artificial intelligence (AI), machine learning (ML), and data science (DS) are evolving from buzzwords to tangible tools that enable operators to make smarter, faster, and safer decisions. At Irth Solutions, these technologies are not just shaping the roadmap for our Asset Integrity for Pipelines (AIP) platform; they’re already embedded in how we transform your data into valuable insights.

This month’s AI in Pipeline Integrity Webinar will bring together Irth’s experts — including Michael Murray (Data Science Team Lead), Noor Amjad (Director of Product), Jordan Dubuc (Chief Architect), and Megan Scudder (Corrosion Product Manager) — to explore how these technologies are redefining integrity management. Here’s a preview of some of the ideas they’ll be discussing and how Irth is already implementing them.

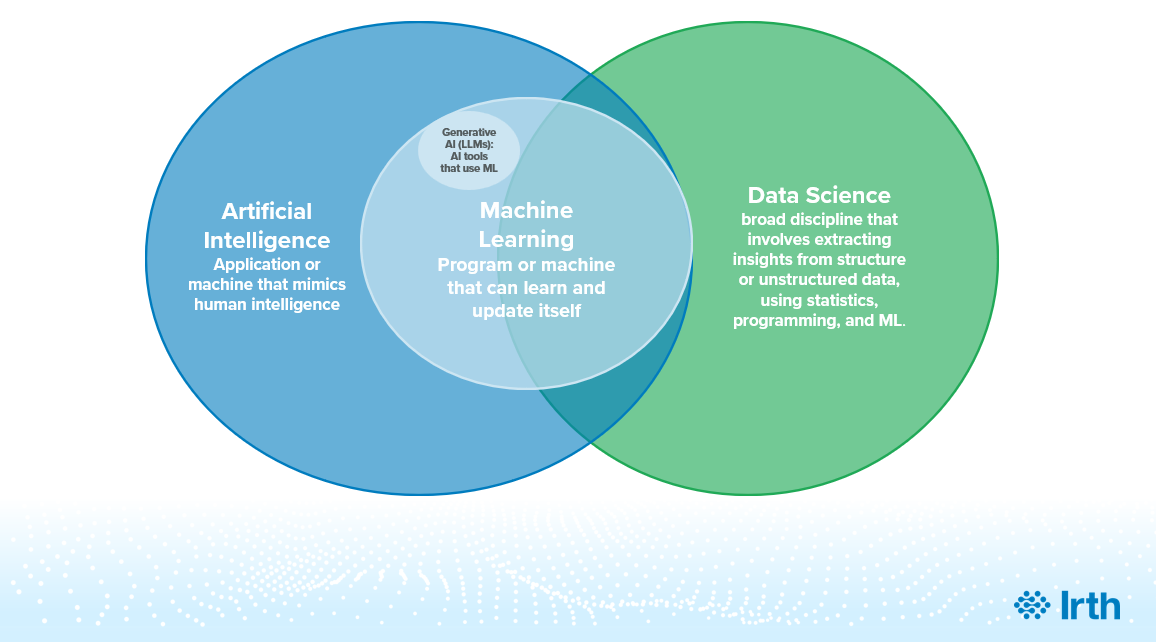

AI refers to any technology that enables computers to simulate human intelligence, from natural language models to predictive algorithms. Machine learning , a subset of AI, allows systems to learn from data without being explicitly programmed, improving performance as they process more information. Data science ties it all together: a discipline focused on extracting insights from large, complex datasets using statistics, programming, and ML.

In pipeline integrity, this convergence allows operators to transform unstructured inspection data — from inline inspection (ILI) reports to CP/CIS surveys — into actionable intelligence. ML models can recognize patterns invisible to the human eye, while data-science workflows ensure the results are explainable, validated, and ready for decision-making.

One of the biggest challenges facing pipeline operators is data quality and structure. Integrity data comes from multiple vendors, in different formats, with varying levels of precision and trust. Before any AI model can make reliable predictions, the data must first be aligned, standardized, and validated. How does one do that, and can we use AI?

AI in pipeline integrity is particularly challenging because an AI chatbot, for example, doesn’t inherently understand that your data represents a physical asset in the ground. Data ingestion into a useful schema and alignment into useful data structures require ML as well as rule-based algorithms before attempting downstream high-value analysis. – Michael Murray, Irth's Data Science Team Lead

It’s imperative to structure your data in a way that AI can “understand.” This requires a combination of expertise in both programming and pipeline integrity, as well as an understanding of how to qualify and structure the data using data science, rule-based algorithms, and machine learning algorithms. A great example of this is AIP's ingestion algorithm.

Irth’s machine learning data ingestion and normalization model, which we’ve been fine-tuning for almost 10 years now (!), tackles data structuring head-on. Using classification algorithms trained on thousands of ILI reports and tens of millions of anomalies, our model interprets every word and number uploaded into AIP, converting them into a consistent format that enables true apples-to-apples comparison across inspections.

Traditional corrosion-growth methods rely on simple two-point depth extrapolation between two ILI runs. Irth’s probabilistic model goes further — it incorporates uncertainty from tool tolerance and measurement variability to calculate a full probability distribution for future wall-loss depth.

By integrating probabilities across every set of possible true depths, this model provides operators with a realistic view of how corrosion may evolve — not just a single prediction, but a range of probable outcomes. The result is a defensible, regulator-ready model that strikes a balance between risk and conservatism, enabling operators to quantify the probability of exceedance and forecast future depths with confidence

In many systems, missing or incomplete data drives uncertainty — and therefore risk. Irth’s ML-based data-imputation model utilizes available attributes (such as diameter, wall thickness, seam type, pipe grade, and MAOP) to predict missing values, including install year or coating type.

This approach not only fills gaps but also helps operators prioritize which missing fields matter most in terms of risk, thereby minimizing time and cost while improving model accuracy.

Internal corrosion accounts for roughly 13% of all pipeline incident costs, and many of those events stem from small, localized pits or pinholes that traditional ILI tools can miss. Irth’s Internal Corrosion Susceptibility Model (ICSM) applies data science and machine learning to identify where bottom-side internal corrosion is most likely to occur, leveraging inline inspection, elevation, and operational data.

The model calculates a susceptibility score for each pipeline segment by combining indicators like pinhole density, corrosion growth activity, elevation valleys, and anomaly orientation. Trained and validated using PHMSA release data, the ICSM pinpoints high-risk regions that align with historical leak locations — helping operators prioritize targeted inspections, chemical mitigation, and preventive maintenance.

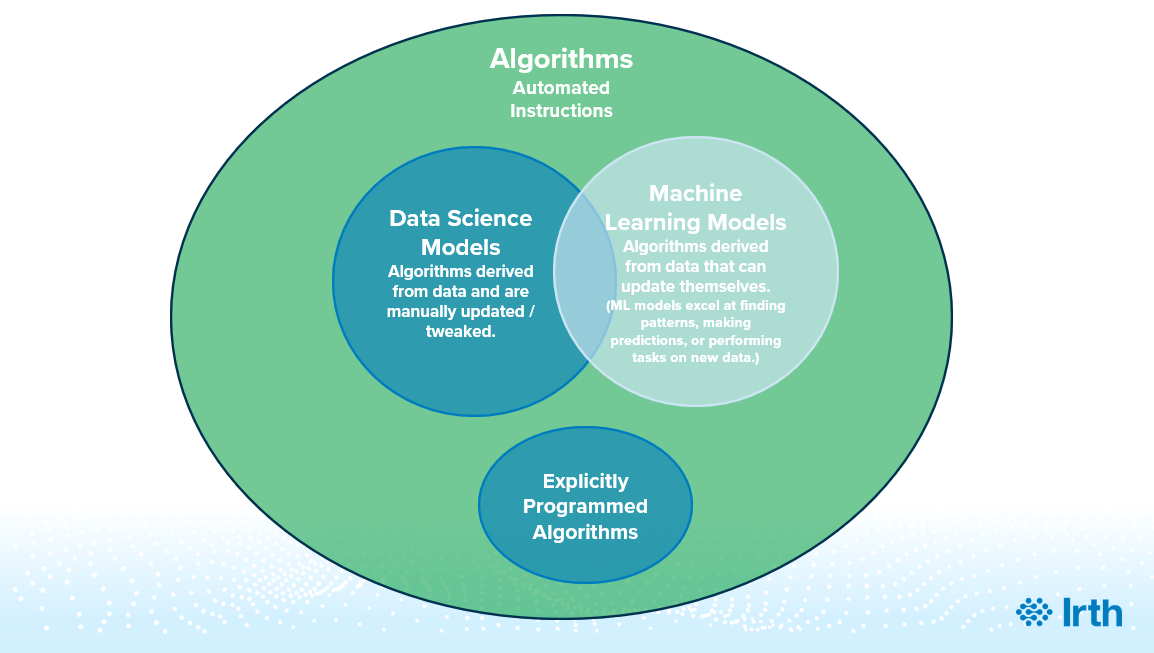

Algorithms are essentially automated instructions that tell a program what to do. Both data-science–driven and machine-learning algorithms derive those instructions from data. The key difference is that data-science models require human updates and intervention, while machine-learning models can update themselves — which is why they can sometimes be perceived as a “black box.”

AI isn’t just transforming integrity management — it’s also reshaping damage prevention through Irth’s Insights™ platform. These machine learning and AI-driven tools analyze millions of 811 tickets, photos, and field records to help operators predict, prevent, and validate potential damage events before they occur.

The Irth Insights™ for 811 Ticket Risk Scoring model predicts the likelihood that an incoming ticket could lead to damage and uses large language models (LLMs) to explain why that ticket is high-risk. The companion Damage Impact Model extends this capability by evaluating not only the likelihood but also the potential severity of a strike, helping operators prioritize their responses more effectively.

AI also drives automation in ticket screening and photo audits — determining which tickets require a locate, verifying photos for accuracy and GPS position, and flagging noncompliant or incomplete documentation. Together, these AI-powered tools enable a smarter, more proactive damage prevention program that continuously learns from outcomes to improve risk scoring, accuracy, and field accountability.

Looking ahead, Irth’s roadmap points toward predictive and generative AI that will automate the integrity-management process end-to-end. Imagine uploading unstructured inspection data and having the system automatically structure, analyze, and summarize results — with risk scores, anomaly trends, and recommended mitigations generated instantly.

Product innovations, such as the Internal Corrosion Susceptibility Model, are already pointing in that direction. Over time, these models could feed into digital-twin environments, enabling real-time risk monitoring and adaptive integrity planning. As always, we’ll look to our clients to understand their needs and priorities when prioritizing roadmap enhancements.

Overall, artificial intelligence and data science are raising the bar on integrity decisions, not by replacing engineers, but by scaling the judgment they already apply.

No AI model is useful if operators can’t trust it. That’s why Irth’s data-science team emphasizes model validation, explainability, and governance. Every model is trained on verifiable data, tested against known outcomes, and continuously retrained as new information is collected.

Using techniques like SHAP (Shapley Additive Explanations), engineers can pinpoint exactly which features influenced a prediction, which is a crucial step toward achieving regulatory defensibility and user confidence.

AI, machine learning, and data science aren’t futuristic add-ons — they’re already embedded in how AIP helps operators modernize integrity management today. By combining scalable data architecture, transparent model design, and real-world validation, Irth is helping pipeline operators move from data-rich and insight-poor to data-driven and risk-intelligent.

To hear more, join us for the AI in Pipeline Integrity Webinar, where Irth’s product and data-science leaders will discuss how these technologies are shaping the next generation of integrity management — and what the future holds.

If you still haven't signed up for our webinar on this topic (how dare you), Register Here.

Why consistent interpretation — not necessarily more data — determines program maturity. External corrosion surveys generate large volumes of...

Integrity analytics doesn't scale without a unfied inspection history. To demonstrate what becomes possible once inspection data is aligned,...