Enterprise External Corrosion Management: Reducing Variability, Increasing Defensibility

Why consistent interpretation — not necessarily more data — determines program maturity. External corrosion surveys generate large volumes of...

3 min read

Sheri Baucom : Updated on December 19, 2025

External corrosion (EC) remains one of the most persistent threats to pipeline integrity. According to PHMSA data, external corrosion is responsible for nearly 20% of hazardous liquid and gas pipeline failures, costing operators an average of $500 million annually in damages and lost service.

The challenge is that EC isn’t caused by a single factor. Soil chemistry, coating quality, cathodic protection effectiveness, climate, and even microbial activity all play a role. Predictive Bayesian models can require up to 50 input variables, making prediction complex, slow, and with varying results.

To identify locations that are at risk of a pipeline failure due to external corrosion, operators have historically relied on:

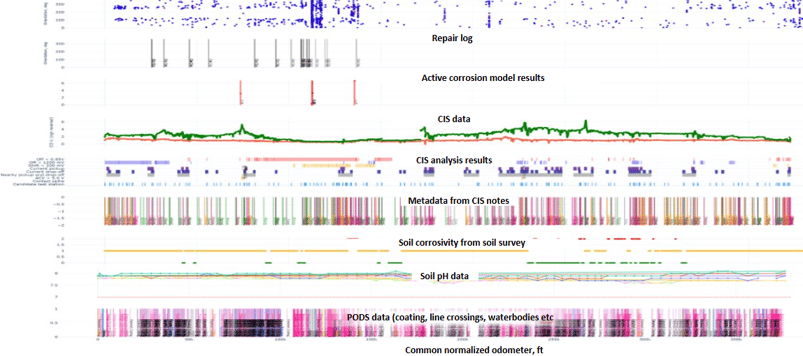

Data scientists at Irth Solutions have introduced a new framework (presented at Rio Pipeline 2025) that applies data science and machine learning to automatically align and process diverse datasets to highlight areas of potential active external corrosion.

The framework has been validated across three operators, 300 inline inspections, and more than 2,580 miles (4,000 km) of pipeline. On average, each CIS contained 70,000+ data points, which the automated framework processed with accuracy and scalability.

This framework doesn’t start from scratch; it builds upon tools already proven within Irth’s Asset Integrity for Pipelines (AIP) platform.

By integrating these tested components into a unified external corrosion framework, operators can act with greater confidence, knowing that the underlying technology has already delivered results in production environments.

Two case studies demonstrate the value of integration:

By synthesizing disparate inputs into a single, normalized view, the framework gives engineers more confidence in identifying where corrosion is active, why it’s occurring, and how to prioritize mitigations.

For integrity teams, the ability to move from raw data to targeted decision-making is transformative. Instead of relying solely on expert interpretation of siloed datasets, operators can leverage an automated, repeatable process that surfaces regions of concern.

While the framework has been applied in the context of external corrosion, it is readily extendable to other threats such as internal corrosion, bend strain analysis using IMU data, or any other applications with pipeline inspection datasets.

The proposed framework offers an efficient, data-driven approach to EC monitoring and decision-making in pipeline integrity management. It automates the labor-intensive aspects of complex CIS data analysis to pinpoint areas of concern for expert review, establishing a foundation for future advancements in predictive maintenance and corrosion mitigation.

The result is not just efficiency, it’s better protection of critical assets. As pipelines age and datasets grow, frameworks like this set the stage for predictive maintenance strategies and data-driven prioritization.

Interested in turning your automating your external corrosion survey data? Schedule your demo of the EC module today.

Why consistent interpretation — not necessarily more data — determines program maturity. External corrosion surveys generate large volumes of...

Integrity analytics doesn't scale without a unfied inspection history. To demonstrate what becomes possible once inspection data is aligned,...