Bringing Integrity and Risk Together Under One Platform

Utilize "best practice" risk models to provide on-demand quantitative risk analysis and reporting.

Risk models were designed and validated by our partner, C-FER Technologies, and utilize integrity data ingested and aligned using machine learning, already contained within the Asset Integrity for Pipelines (AIP, formerly CIM) platform.

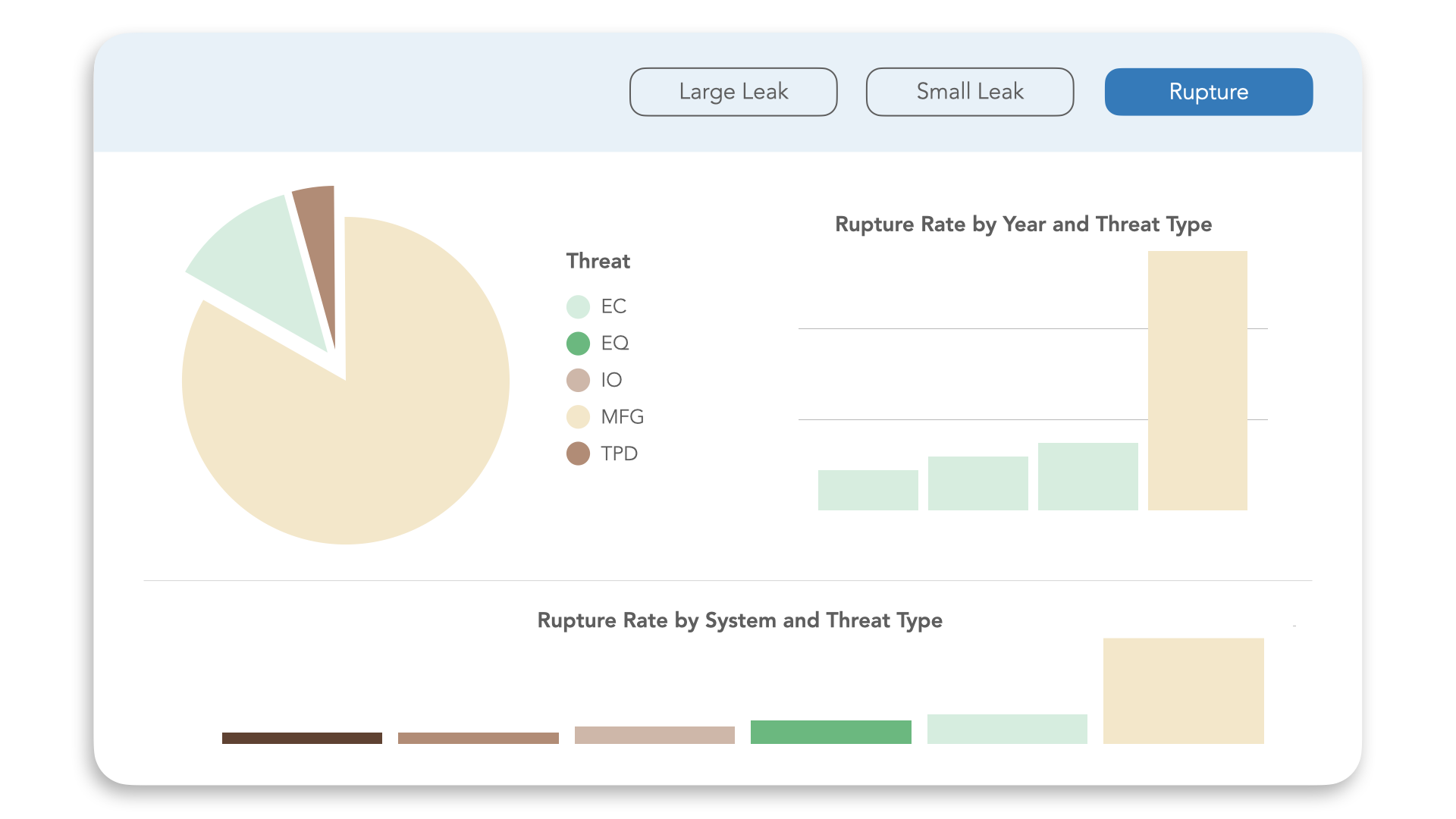

The Risk Management Module assesses risk from two different perspectives:

Structural Reliability models calculate the probability of failure (POF) using inline inspection (ILI) data for the following threats: external corrosion, internal corrosion, stress corrosion cracking, and mechanical damage (aka third-party damage).

Historical Incident models calculate the POF using historical incident data from PHMSA for the following threats: equipment failure, incorrect operations, manufacturing defects, fabrication defects, and weather and outside forces.

Powerful Benefits of Our Risk Management Module

Quantitative Risk

Delivers on-demand, quantitative risk analysis using best practice models designed and validated by C-FER Technologies.

Integrated Data

Integrates and aligns diverse integrity data, i.e., inspections, GIS, incident reports, and repair records, into a centralized platform.

Reliable Results

Models are uniquely trained and validated on a simulation of 3.5 million mile-years and calibrated to failure rates derived from the PHMSA incident database.

Data-Driven

Replaces outdated qualitative assessments with probabilistic, data-driven insights that account for uncertainty and drive informed decision-making.

Dynamic Threat Scoring

Calculates a real-time threat score that is updated dynamically as new integrity data is ingested into the platform.

Actionable Insights

Enables scalable, enterprise-wide visibility into pipeline risk via automated dashboards and customizable reports.

Request a Demo

Request a Demo

More Than a Learning Management System (LMS)

Train workers and simplify the complexity of governance and compliance to mitigate risk with data and reporting.

Continuous Improvement

Create learning paths to make it easy for people to learn with the ability to continuously improve your trainings.

Flexible Features

Scalable and flexible user management features for users and user groups.

Competency Metrics

Quality assurance assessments and training make it easy to track training competency metrics.

Certifications

Manage team’s certification and continuing education progress.

Reduce Risk and Prevent Damages with Intelligent Forms & Workflows

Our intelligent forms provide additional capabilities and insight into your workflow and assets. All forms work seamlessly to allow users to gain visibility into their daily operations.

Monitoring

Automatically trigger a monitoring activity to ensure each excavation is performed accurately and safely.

Locate Audit

Capture and score locates, identify technician training gaps, optimize field resources, and improve the accuracy of locate services and mapping.

Pre-Excavation Checklist

Ensure technicians are following regulations and processes with the Pre-Excavation Checklist form.

Damage Investigation

Collect data on critical damage, near misses, and more to help improve safety and overall processes.

811 Ticket Management

Comprehensive one call ticket management

Predictive and prescriptive analytics with AI

Automated ticket screening, routing, and dynamic dispatching

Automated positive response to one call and excavators

Accurate geo-location mapping and map layers viewable whether online or offline

Document and image attachments

Native applications for iOS, Android, and Windows

Fully configurable workflows for field operations (locate audits, damage investigations, claims processing, etc.)

Automated, customizable workflows

Work portal for tasks, alerts, and notifications

Reporting and analytics featuring Microsoft Power BI

Seamless integrations with internal and external systems

Locate accuracy and training

One Integrated Solution for Integrity and Risk

The Risk Management module breaks down silos within teams (risk and integrity) as well as data, providing a centralized platform for ingesting, aligning and standardizing integrity data for on-demand risk analysis and reporting.

By centralizing data characterizing the pipe, environmental, maintenance activity, and operating conditions, the platform is able to leverage its proven machine learning based alignment along with scalable quantitative and probabilistic risk modeling to extract deep insights.

This allows operators to utilize real-time risk analysis in day-to-day integrity decisions to usher in a new era of pipeline safety, from reactive to proactive and ultimately predictive, thereby enhancing the opportunity to reduce pipeline failures.

Resources

Articles, Case Studies, News, and More

The latest industry news, interviews, technologies, and resources.

Introducing Risk Management for Pipelines: Quantifying Threats

Irth: Apr 24, 2025

Pipeline Risk Management – Handling Uncertainty

Irth: Aug 6, 2024

Join our newsletter

We’ll send you a nice letter once per week. No spam.

When it comes to damage prevention, nobody has Irth’s experience with 811 ticket management.

Our customers in the energy, gas utility, telecommunications, and electric utility industries have millions of miles of pipelines, cables, and critical network infrastructure that need constant, vigilant protection. We understand that one misguided excavation can result in serious injury to workers or a massive outage that could be crippling to business and communities.

By using Irth’s cloud-based platform, companies can electronically receive, respond to, and resolve excavation requests. Our solution is connected to every one call center in North America, so you can manage 811 tickets no matter where your critical network infrastructure is. Our technology is also constantly updated to adhere to regulations across all states, provinces, and territories. We’re committed to ensuring your critical assets are functioning and protected from potential damage.

Protect your critical infrastructure, improve public safety, and meet time-sensitive regulations — all from one platform.

Join Our Newsletter

Stay ahead with curated insights delivered monthly.

Irth’s market-leading SaaS platform improves resilience and reduces risk in the sustainable delivery of essential services that millions of people and businesses rely on every day. Energy, utility, and telecom companies across the U.S. and Canada trust Irth for damage prevention, asset integrity, land management, and training solutions. Powered by business intelligence, analytics, and geospatial data, our platform helps deliver the 360-degree situational awareness needed to proactively mitigate and manage risk of critical network infrastructure in a changing environment. Irth has been the top provider for 811 (one call) ticket management and utility locating software since 1995.

Contact

5009 Horizons Drive

Columbus, OH 43220

© 2026 Irth Solutions, L.L.C.