Asset Integrity

Elevate Your Asset Integrity Program

Pipelines traverse nature preserves, parks, water supplies, businesses, and our communities. That's why it's paramount to apply the latest technology to managing pipeline integrity which allows for proactive measures to ensure pipeline safety, reliability, and compliance.

Irth Asset Integrity for Pipelines (AIP, formerly CIM), a fully integrated enterprise-level solution built on the highly secure Microsoft Cloud, gives owners a systematic approach to managing the integrity of their critical assets effectively. It leverages advanced data science and machine learning to enable pipeline operators to make efficient data-driven decisions to prevent pipeline failures and protect the safety of people and the environment.

Data Integration & Alignment Using ML

Harness machine learning (ML) to ingest any inline inspection (ILI) report, regardless of vendor or format. Effortlessly integrate and align your ILI reports, pipeline data, external corrosion surveys, internal corrosion control activities, and even repair data for advanced condition and threat analysis.

Enterprise Risk Management

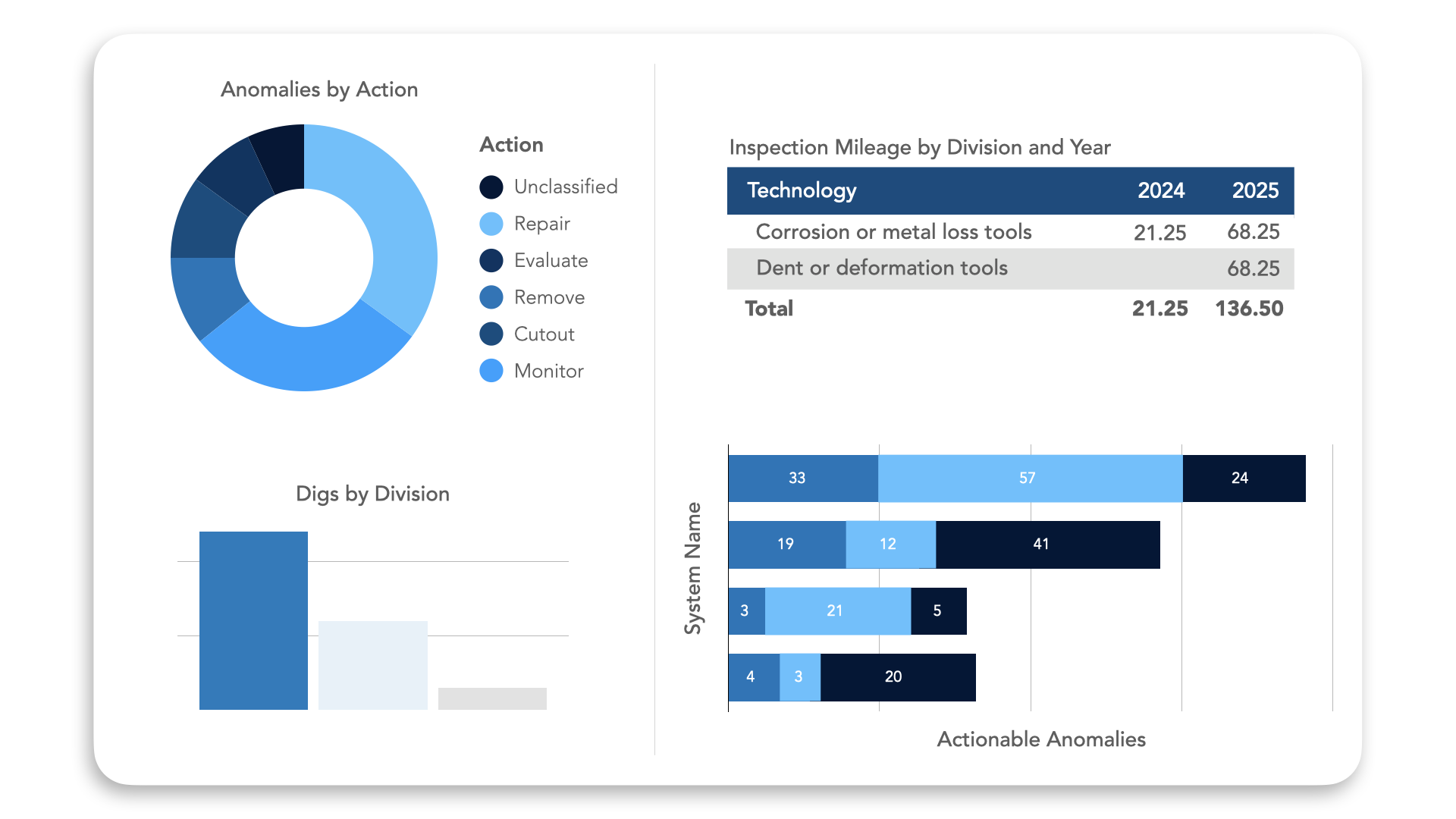

Understand and visualize threats to your assets through correlated datasets, engineering analyses, built-in data science models that predict points of failure, and enterprise Power BI dashboards and reporting. Use a single platform to quantify risk, allowing for quicker data-driven decision-making.

Elevating the Industry

Ushering in a new era for pipeline safety by digitally transforming asset integrity programs, eliminating data silos and providing a holistic view of asset risk. Providing a platform for sharing knowledge and insights through our analysis condition library, annual State of Integrity reports, and User Summits.

Inline Inspection

Fully comprehensive inline inspection data management.

Centralize and analyze inline inspection data using ML to automate assessment planning, anomaly classification, and regulatory compliance.

Perform advanced engineering evaluations (e.g., burst pressure, corrosion growth, fitness-for-service) to support risk-based decision-making and reassessment planning.

Streamline end-to-end workflows from inspection to repair with dig planning tools, automated reporting, GIS integration, API 1163 analyses, and a secure vendor portal.

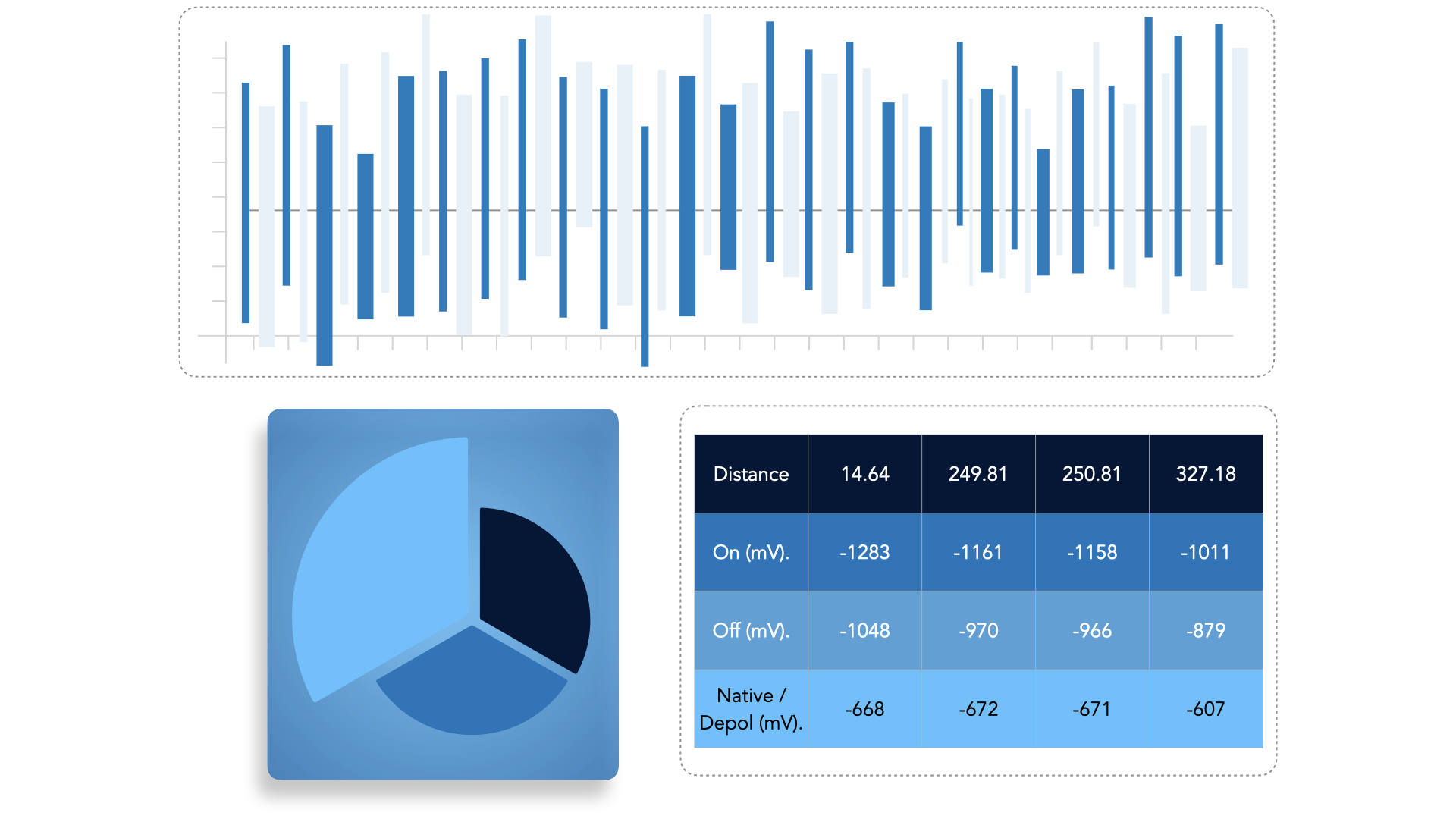

External Corrosion

Turn your external corrosion control surveys into actionable insights.

Align & integrate external corrosion control surveys with ILI and pipeline data.

Analyze corrosion control survey data with pre-built SME-designed conditions.

Identify deficient regions, create mitigation plans and track workflow actions.

Internal Corrosion

Integrate varied internal corrosion control activities to assess program effectiveness

Integrate coupon, pigging, ILI, chemical, and operational data into a single platform.

Detect active internal corrosion and evaluate mitigation effectiveness.

Streamline tracking and reporting with enterprise-level dashboards, automated KPIs, and tools to manage tasks, expenses, and continuous improvement.

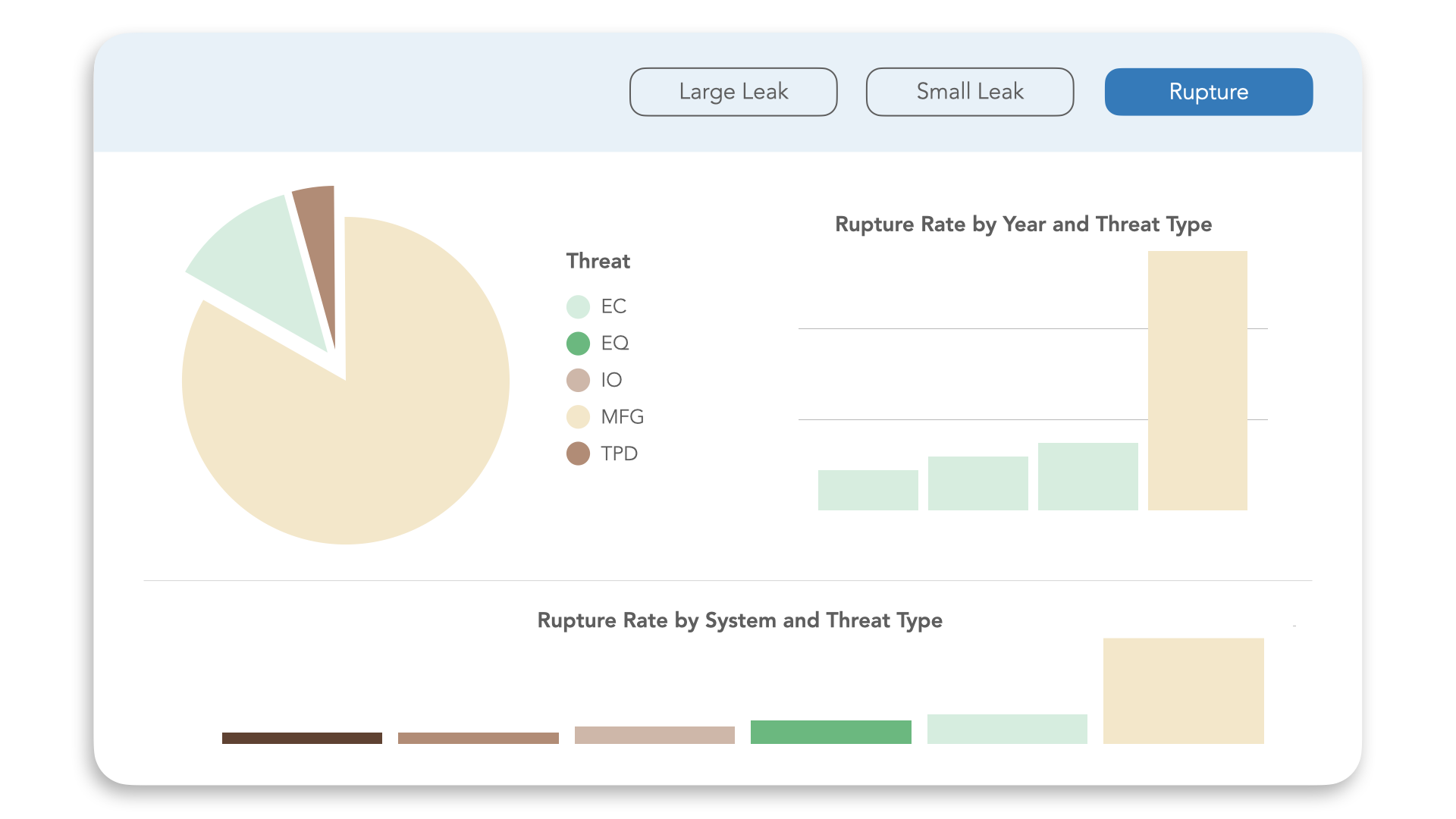

Risk Management

Utilize "Best Practice" risk models to provide on-demand quantitative risk analysis and reporting.

Assess the 9 threat categories from ASME B31.8S utilizing a combination of structural reliability and historical-based models.

Quantify the real-time probability of failure in meaningful units.

Utilize models designed by C-FER Technologies and validated by PHMSA data.

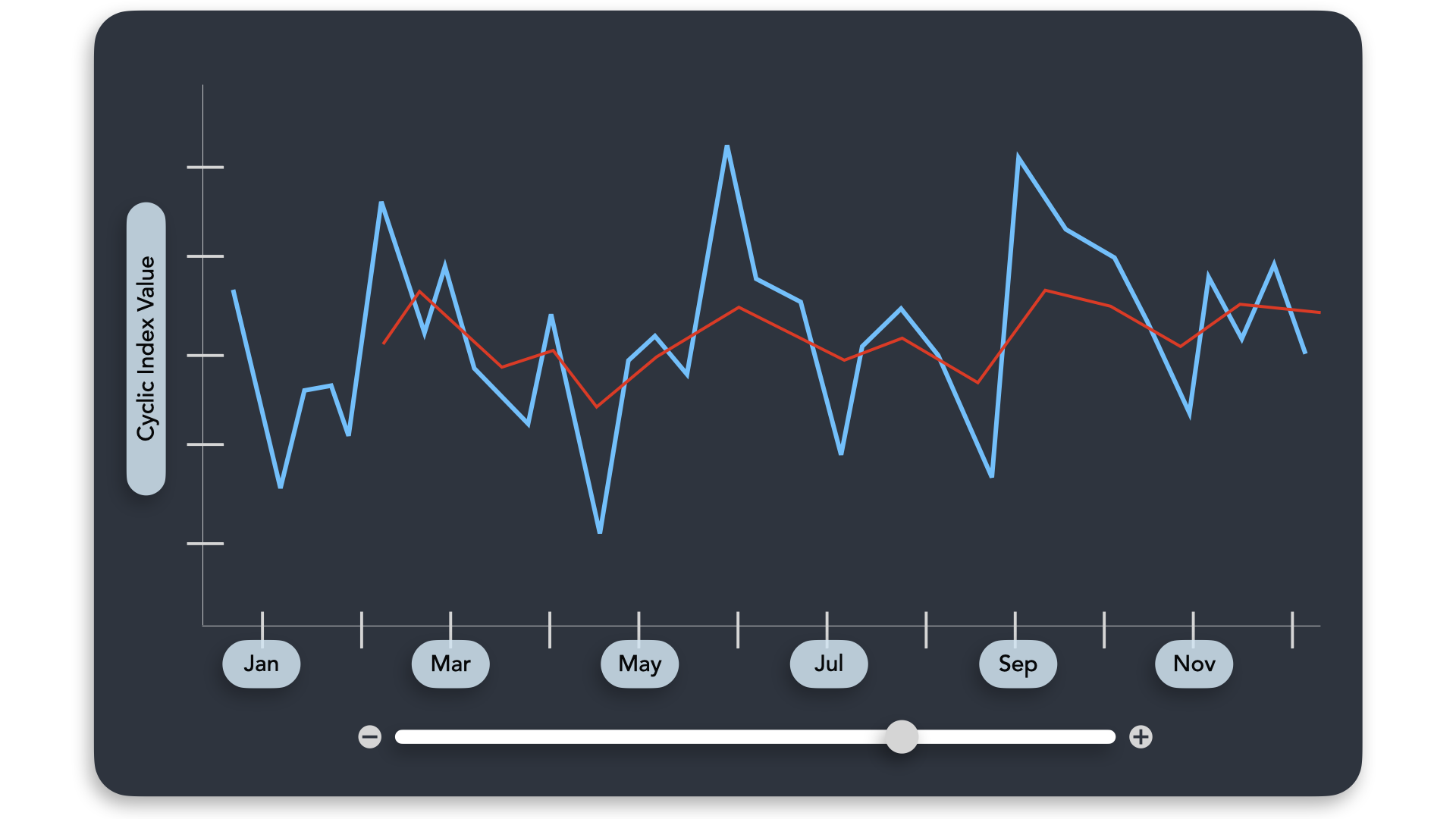

Advanced Crack

Perform pressure cycle fatigue analyses on cracks identified from inline inspection data.

Determine the severity of pressure cycle fatigue at each flaw location.

Estimate the fatigue growth rate and remaining life, using MAT-8.

Perform "what-if" scenarios with different pressures & material properties.

Geohazards Management

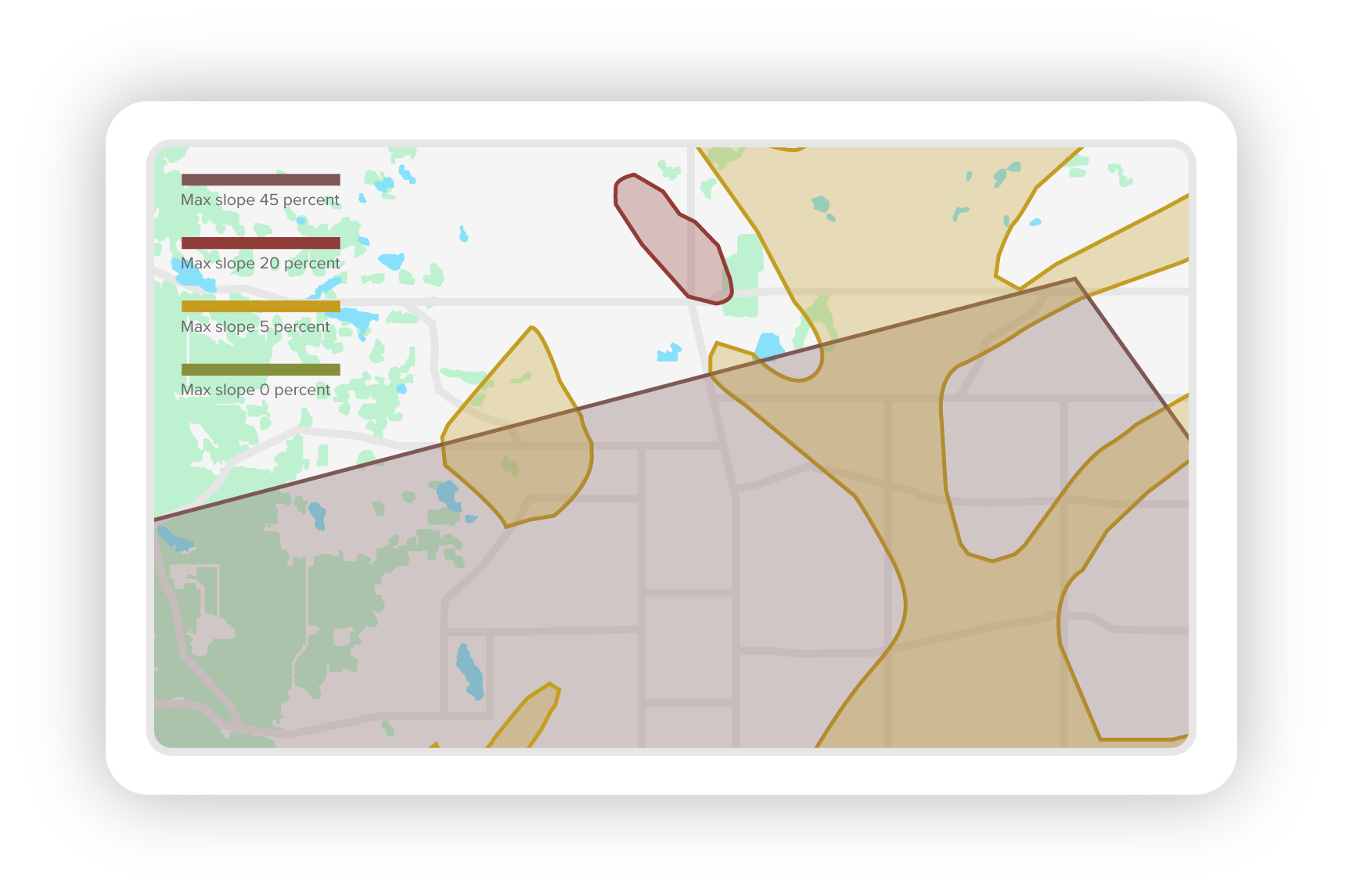

Unify geospatial intelligence with pipeline integrity data to assess and manage environmental risk.

Identify where environmental hazards intersect pipeline assets using integrated geospatial datasets.

Correlate inspection findings, bending strain, and field observations to understand geohazard impact.

Prioritize geohazard threats with spatial context to support confident integrity decisions.

Risk Management Add-On

The Risk Management module provides a centralized platform for integrating a holistic data set characterizing the asset, environment, maintenance activity, and operating conditions. Said data is utilized to drive a scalable quantitative and probabilistic risk model that allows for real-time risk analysis results for use in day-to-day integrity decisions.

Professional Services

Our GIS analysts and pipeline integrity engineers will support your integrity management program with a combination of expertise and software. Capabilities include:

Risk Assessment

Hazardous Liquid High Consequence Area Analyses

Gas Consequence Area Analyses

Valve Studies

Integrity Assessment Support

Crack Anomaly Fitness-For-Service

Data Prediction Using Machine Learning

Compliance Services

Latest Posts

Blogs

Deploying Probabilisitic Corrosion Forecasting at Scale: What Unified Data Makes Possible

Sheri Baucom: Feb 12, 2026

From Unified Data to Scalable Automation

Sheri Baucom: Feb 2, 2026

Join Our Newsletter

Stay ahead with curated insights delivered monthly.